NOV Strix視覺技術進行粘貼高度檢測(SHD)

使用攝像機來優(yōu)化鉆孔過程的視覺技術(Vision technology)。

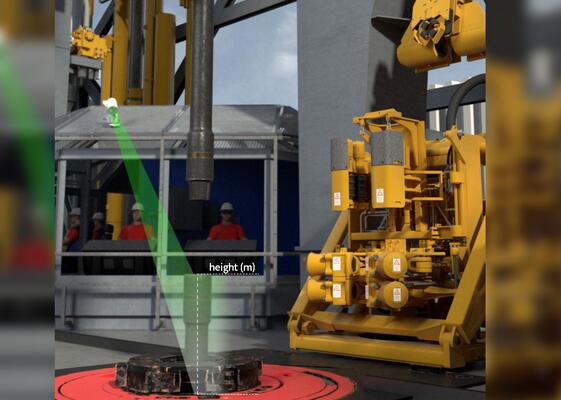

Strix系列視覺技術可以幫助您改進目前已經(jīng)達到了實際限制的解決方案的過程自動化,過程優(yōu)化和增強安全性。該技術使用高清晰度攝像機和快速圖像處理來自動操作鉆孔過程,否則將需要操作員的手動干預。雖然該技術有許多可能的應用,但我們目前提供的Strix視覺技術主要用于自動化粘貼高度檢測(SHD)。

鐵鉆的水平和垂直移動通常是獨立的軌跡,在工具輔助下安裝的傳感器可以檢測管道和工具接頭頸。標準進程需要操作員目測確認正確的鐵顎夾爪位置,并在需要時手動調整刀具高度。通過使用攝像機和視覺算法,可以獲得準確的管道粘貼高度。該控制系統(tǒng)使用粘貼高度值,將鐵鉆從停放位置移動到指示的正確位置,同時執(zhí)行水平和垂直運動(參見圖2)。優(yōu)化軌道減少了鐵鉆進入和站立所需的總體時間。

注:該文章由鼎恒石油編譯,轉發(fā)須注明出處。

附英文原文:

Strix™ Stickup Height Detection

Vision technology that uses cameras to optimize the drilling process.

The Strix family of vision technology answers your call for improved process automation, process optimization and enhanced safety where current solutions have reached their practical limits. The technology uses a high definition camera and fast image processing to automate drilling processes that otherwise would require an operator’s manual intervention. While there are many possible applications for this technology, we are currently offering Strix vision technology for automatic Stickup Height Detection (SHD).

Horizontal and vertical movements of the iron roughneck are typically independent trajectories, aided by tool-mounted sensors detecting the pipe and tool joint neck. The standard process requires an operator to visually verify correct iron roughneck jaw position and manually adjust the tool height if needed. By using a camera and vision algorithms, accurate pipe stickup height is obtained. The control system uses the stickup height value and commands the iron roughneck from parked position to the correct make-up position performing simultaneous horizontal and vertical movements (see Figure 2). The optimized trajectory reduces the overall time needed for trip-in and stand building.